1. What is Operational Excellence?

“As the lean movement evolved from learning about quality in the 1980’s to learning about the Toyota Production System in the 1990’s to Lean Six Sigma in the 2000’s, … it lost people and it lost purpose along the way.”[1]

Toyota did not seek to “deploy” tool sets like Lean and Six Sigma or “implement” a Continuous Improvement Culture. Instead, senior leaders would ask the question “Why are you doing this?”, teaching people how to think. And, as illustrated by Jeffrey K. Liker, achieving Operational Excellence would be expressed as the ultimate purpose of the Toyota Production System. [2]

Operational Excellence therefore got picked up as a subject on its own explicitly in the 2010’s. Neither a specific management philosophy nor a particular methodology, it is seen as an integration of all of those enabling to reach Excellence including, but not limited to, Lean Thinking, Six Sigma, Scientific Management, Organisational Design and Leadership Development.

Roger Price summed it up as “building a sustainable competitive advantage through operations management”.[3] Kevin Duggan took these ideas one step further in his book “Design for Operational Excellence: A Breakthrough Strategy for Business Growth”,[4] in which he posits that for true success, we need to connect our improvements so that we achieve a destination of Operational Excellence that will drive business growth.

He debunks the myth of continuous improvement as a never-ending journey towards a goal or vision and replaces it with the idea of Operational Excellence been understood as an exact destination, one that can be taught to people. He therefore defines Operational Excellence as the creation of an operation where each and every employee can see the flow of value to the customer, and fix that flow before it breaks down.[5]

Furthermore, Duggan describes a set of 8 principles that, if consistently applied in the bespoke sequence, will lead to an organisation achieving that target state in the fastest way possible, proven by the three case studies of Parker Hannifin Corp., IDEX Corp. and Hypertherm. Those principles are:[6]

- Design lean value streams

- Make lean value streams flow

- Make flow visual

- Create standard work for flow

- Make abnormal flow visual

- Create standard work for abnormal flow

- Have employees in the flow improve the flow

- Perform ‘offense activities’ (activities that generate business growth)

Given that these principles clearly had evolved within manufacturing environments, Duggan went on to illustrate how these principles could be applied within a service environment in his “Operational Excellence in Your Office”[7] and “Beyond the Lean Office”.[8] In those, he provided practical approaches to understanding and managing service value streams while addressing the real world complexity of high-mix service environments, like five questions for flow in the office that are empowering and drive office employees to create not just flow, but a self-healing, autonomous flow that does not require management intervention.

More recently, Joseph F. Paris Jr. supported the view of Operational Excellence as the ultimate purpose, the destination a leadership team would ultimately strive for aiming to achieve a competitive advantage, when he proposed the following definition of Operational Excellence:

“A state of readiness attained as the efforts throughout the enterprise reach a state of alignment for pursuing its strategies – where the corporate culture is committed to the continuous and deliberate improvement of company performance AND the circumstances of those who work there – and is a precursor to becoming a high-performance organisation.”[9]

Notwithstanding the fact that business improvement methodologies like TPS, Lean Six Sigma, and Process Improvement, which placed their emphasis on processes to gain a competitive advantage, have yielded tremendous success, he posits that “the twenty-first century company will need to go beyond processes and place its emphasis on optimised systems to remain competitive, even viable.”[10] Paris stresses the need to lead change, to ready the company to see major challenges early and maximise its preparedness to engage, and, when the time for action comes, quickly shift from strategy development to strategy execution.

2. The Race Towards Excellence: A Personal Perspective

I find Kevin Duggan’s view of Operational Excellence as an exact destination very compelling, a state that can be achieved by applying specific principles, and that to arrive at a destination, we must not only create just flow, but a self-healing, autonomous flow of value that does not require management intervention. I am equally convinced of Joseph F. Paris jr.’s perspective of Operational Excellence as the ultimate purpose, the destination.

The “state of readiness” to act requires an alignment of efforts throughout the enterprise to pursue its strategies and a corporate culture committed to the continuous and deliberate improvement of company performance, including the circumstances of those who work there. When we achieve that destination, the organisation will be seen as a high-performance organisation, one that most of its members will be very proud of belonging .

In my view, we must therefore develop organisations with the following characteristics:

i. Being Strategy Focused

A strategy-focused organisation is guided by a clear and overriding purpose or raison-d’être, a corresponding vision and mission; an organisation that pursues a strategy derived from its purpose and traces progress of action plans that at the same time are based on an honest reflection of its current condition vs. the desired future state.

In such an organisation, policy will be deployed not only to the lowest level of the organisation, but first and foremost, translated into outcomes for each customer journey and performance for every end-to-end process. Customer Journey owners and End-to-End process owners will own that performance, in other words: be held accountable for it.

At the same time, they will be given the appropriate decision and influencing power to steer the company’s operations in a way that achievement of those objectives remains everyone’s number one.

The Balanced Scorecard will serve as means to reflect the strategy and be cascaded down in the form of performance dashboards with regular dialogues conducted to review the actual results displayed, leading to the identification of countermeasures when and wherever required. Rather than an “Office of Strategy Management” (OSM) as posited by Norton and Kaplan,[11] this consistent performance management cascade will be used as the tool to drive rigorous execution and identify current or potential future deviations as early as possible.

ii. Being Customer-centric & Process-oriented

A customer-centric (outcome-driven) and process-oriented organisation: I share Janne Ohtonen’s view that the most dramatic changes to an organisation’s efficiency and performance may come through an alignment of customer experience with business architecture and innovation.[12]

Today, high-performing organisations like Amazon, Airbnb, Booking.com or have mastered to start thinking outside-in, i.e. to view any existing or new product or service offering strictly from their customer’s perspective first and design the customer touch-points and experiences accordingly instead of falling into the still rampant habit of taking an inside-out perspective, failing to provide memorable customer experiences because the team limits itself by the process capability of today’s business infrastructure.

Knowing and understanding the customer from the first touch with the business throughout their whole life-cycle, and ensuring this understanding translates to true value that grows over time, these companies have connected the business – from front to back – around the customer. To achieve this, customer journeys and value chains have become the principle element around which people are organised, led, incentivised, and managed on a long-term as well as short-term basis rather than functional silos still prevalent.

Functions may still continue with specific expertise and skill set who can be employed to achieve a particular outcome as part of the value-creation process, but may lose relative importance.

iii. Where Leaders don’t create followers, but new leaders

An organisation where leaders don’t create followers, but new leaders, and decisions are made as close as possible to those who have the necessary information (leadership is distributed): A keynote speaker on a top management conference at a former employer stated that “the pace of change in the world will never again be that slow as today – the speed of transformation is only going to increase”. And it affects organisations in a big way as lifespans of top companies are shrinking, according to an Innosight study of the S&P 500 Index:[13]

- US corporations in the S&P500 in 1958 remained in the index for an average of 61 years. By 1980, the average tenure of an S&P500 firm was 25 years, and by 2011 that average shortened to 18 years based on seven year rolling averages. In other words, the churn rate of companies in the S&P500 has been accelerating over time.

- At current churn rate, 75% of the S&P 500 will be replaced by 2027

If that holds true, an organisation that sticks with the traditional “leader-follower” paradigm won’t be able to keep pace with one that adopts the “leader-leader” paradigm and the transformational leadership style demonstrated by L. David Marquet.[14] The future won’t be created by one single person “at the top”, but be built by people who have discovered that leadership is the enabling art of releasing human talent and potential.

A human being’s genius, passion, loyalty and tenacious creativity can’t just be bought with a paycheck – it needs to be volunteered. For this to happen, we need leaders who are able to create environments where people feel safe and like to belong, so everyone will feel encouraged to bring in their ideas to make their leader’s inspiring vision come true.

iv. Deliberately continuously improving & learning and more agile

The distinguishing feature of Taiichi Ohno’s approach when he created the Toyota Production System in the 1970’s[15] was to engage the whole workforce in seeking improvements rather than relying solely on experts, resulting in an engaged workforce with superior problem-solving skills, operating within an organisational culture and infrastructure that genuinely saw mistakes as opportunities to improve, encouraged knowledge sharing and rewarded adoption of good practices.

Now, about 50 years after this ingenious concept was invented, any high-performing organisation should be able to replicate. Not only has the knowledge how to get there been widely shared, but western economies have meanwhile gained practice from production into service sectors and new employees demand to be led in a different way than their predecessors.

At the same time, we have learned how to replace traditional waterfall project management methodologies with agile-like project management, acquired new techniques like design thinking and rapid prototyping, and to see mistakes as learning opportunities, openly sharing with colleagues. All of the above adds up to a high-performance organisation as one that…

Delivers world-class operational performance, is the benchmark for its competitors, admired by its customers, praised by its investors, recommended as great place to work by its associates. Indeed, such companies often develop exemplary ethical and environmental behaviour appreciated by wider society.

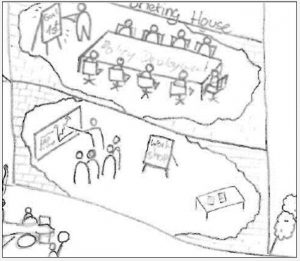

3. Visualising ‘The Race of Excellence’

Having run an “Operational Excellence for Senior Leaders” programme across three different organisations during 2018 and 2019, I wanted to concisely convey all of these ideas, showing how they function together. My initial thoughts were to develop a ‘mountain climbing’ model, but felt this may have left people with the question “so what, once we have arrived at the mountain top, what then?” – a one-off event.

My colleague Julius Heruth and I finally arrived at the analogy of a racetrack – like Simon Sinek says, “it’s about an infinite game” – one lap representing one time cycle, maybe a month or a year, and then the whole thing starts again [16].

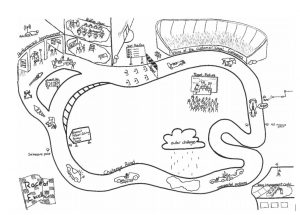

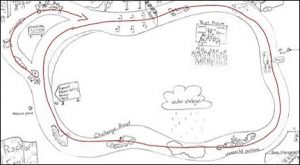

The concept is thus visualised as single picture – ‘The Race of Excellence ‘.

Figure 1: The Race of Excellence (developed by Jörg Baier, drawn by Julius Heruth)

The following table describes each of the above picture’s elements in detail, providing an idea how those are interlinked and at the same time listed in the order in which I recommend those elements to be introduced into an already existing organisation (if not yet established there).

|

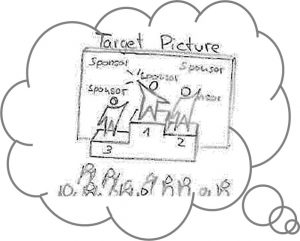

(14) The Race: What do you do when you are playing in a game that has no finish line? In the Infinite Game, the goal is not to win – the goal is to get better. To indicate that most organisations are to adopt an infinite mindset, the “Race of Excellence” is taking place on a racetrack where each passing of the finish line means a new lap is being started.

Yes, the specific race is over at some point, giving us time to maintain and improve our equipment, replace broken parts, rewire our brains, retrain and up-skill our team, review and adjust our strategy and respective plans, and improve the way we operate. |

|

(15) The Finish Line: This pause basically means a shift of activities from one field to another one, not that we can stop being busy. And within a week or two, there is another race to come … As Simon Sinek posits,[16] changing our mindset away from having competitors – other players to be beaten – and rather to adjust that mindset to see those other players as worthy rivals, there to reveal to us our weaknesses so that we may become better versions of ourselves, is the right mindset for the infinite game. The state of Operational Excellence is dynamic and not static – we therefore must stay nimble, flexible, open-minded, agile and ready to sense any changes in the environment, carefully assess whether things are changing, remaining alert in case they are. Once we decide to act, we act decisively and execute rapidly. |

|

(16) The Podium: Luckily, there is time to celebrate success after each race. This is also the time to demonstrate respect for people, recognise and reward meaningful contributions and outstanding performance.

You want to identify good practices and turn them into new standards. It is therefore as well the time to encourage your most capable team members to share their insights and experiences to develop their colleagues. |

Figure 2: The Race of Excellence explained

In Conclusion…

My colleagues and I at E.ON SE have been supporting senior leaders in developing their respective organisations towards operationally excellent ones, employing this model. We have been able to use the logic and sequence of the model to help to build respective capabilities with ‘The Race of Excellence’ approach, yielding desired outcomes and giving valuable feedback, much appreciated by the participants. Each organisation and leadership team is different however, so the approach used should be tailored to their needs.

Jörg M. Baier, February 2020

Literature

- Anthony, S.D., Viguerie, S.P., Schwartz, E.I., Van Landeghem, J. [2018]: 2018 Corporate Longevity Forecast: Creative Destruction is Accelerating, https://www.innosight.com/insight/creative-destruction, retrieved 26 October 2019

- Duggan, K.J. [2012]: Design for Operational Excellence: A Breakthrough Strategy For Business Growth, ISBN 978-0071768245

- Duggan, K.J. [2016]: Beyond the Lean Office: A Novel on Progressing from Lean Tools to Operational Excellence, Productivity Press, ISBN 978-1498712484

- Duggan, K.J., Healey, T. [2016]: Operational Excellence in Your Office: A Guide to Achieving Autonomous Value Stream Flow with Lean Techniques, Productivity Press, ISBN 978-1498714082

- Kaplan, R.S., Norton, D.P. [2008]: The Execution Premium: Linking Strategy to Operations for Competitive Advantage, Boston, Massachusetts, ISBN 978-1422121160

- Marquet, L.D. [2015]: Turn The Ship Around: A True Story of Turning Followers Into Leaders, Great Britain, ISBN 978-0241250945

- Netland, T., Powell, D.J. (Editors) [2017]: The Routledge Companion to Lean Management,

New York, ISBN 978-1138920590 - Ohno, T. [1988]: Toyota Production System: Beyond Large-Scale Production, New York 1988; an English translation of: Toyota seisan hōshiki, Tokyo, ASIN B00M0PZXNM

- Ohtonen, J. [2013]: You Think You Are Doing Well? Become a Winner with Customer-Centric Process Leadership, Helsinki, ISBN 978-9526805504

- Paris jr., J.F. [2017]: State of Readiness: Operational Excellence as Precursor to Becoming a High-Performance Organization, Austin, Texas, ISBN 978-1626343115

- Price, R. [2015]: What is Operational Excellence and How is it Measured?, https://www.eonsolutions.io/blog/what-is-operational-excellence-and-how-is-it-measured, retrieved 26 October 2019

- Sinek, Simon [2019]: The Infinite Game: How Great Businesses Achieve Long-Lasting Success, ISBN 978-0735213500

References

[1] Liker, J. in: Duggan, K.J. [2012]: Design for Operational Excellence, p. vii

[2] See Liker, J. [2017]: The Toyota Way: Striving for Excellence, in: Netland, T., Powell, D.J. (Editors) [2017], p. 13

[3] See Price, R. [2015]: What is Operational Excellence and How is it Measured?

[4] Duggan, K.J. [2012]: Design for Operational Excellence

[5] Duggan, K.J. [2012]: Design for Operational Excellence, p.26

[6] Duggan, K.J. [2012]: Design for Operational Excellence, p.123

[7] Duggan, K.J., Healey, T. [2016]: Operational Excellence in Your Office

[8] Duggan, K.J. [2016]: Beyond the Lean Office

[9] Paris, J.F. [2017]: State of Readiness, p. 10

[10] Paris, J.F. [2017]: State of Readiness, p. 75

[11] Kaplan, R.S., Norton, D.P. [2008]: The Execution Premium: Linking Strategy to Operations for Competitive Advantage

[12] Ohtonen, J. [2013]: You Think You Are Doing Well? Become a Winner with Customer-Centric Process Leadership

[13] Anthony, S.D., Viguerie, S.P., Schwartz, E.I., Van Landeghem, J. [2018]: 2018 Corporate Longevity Forecast: Creative Destruction is Accelerating

[14] Marquet, L.D. [2015]: Turn The Ship Around: A True Story of Turning Followers Into Leaders

[15] Ohno, T. [1988]: Toyota Production System: Beyond Large-Scale Production

[16] Sinek, S. [2019]: The Infinite Game: How Great Businesses Achieve Long-Lasting Success