This article was written by Simon Elias of the LCS and Richard Harrison of Sales Transformation Partnership.

Introduction

While lean thinking is increasingly being applied beyond the operations arena in many organisations, sales and marketing (S&M) appears to have been particularly immune to the lean mantra. The reasons behind this are not particularly well documented or researched and probably include the reluctance of S&M managers to view what they do as definable ‘processes’, a belief that they operate in a black box world of relationships and the art of selling and that all the ‘lean stuff’ is just for the shop floor.

At this stage it is worth noting that the term ‘sales and marketing’ covers a broad array of activities, including sales management, business development, advertising, market research and planning, product development, direct marketing, communication, PR, etc. Furthermore, there are different sectors – for example, FMCG, consumer durables, business-to-business (B2B) – each of which have their own approaches and methods. This article’s focus is the classic sales management and business development function in B2B relationships and while lean principles and techniques can no doubt be applied to all areas, a degree of adaptation will invariably be required.

Engaging with the S&M Audience

Lean’s focus on identifying and delivering value to customers should make it a prime concern of S&M people, who are generally charged with that task in many organisations. Most lean advocates would probably claim that the concepts and principles of lean are just as relevant to the S&M function as any other part of the organisation, since the need for short lead times, high quality, even flow of activities, minimising waste, continually improving are just as applicable to selling the business’s products or services.

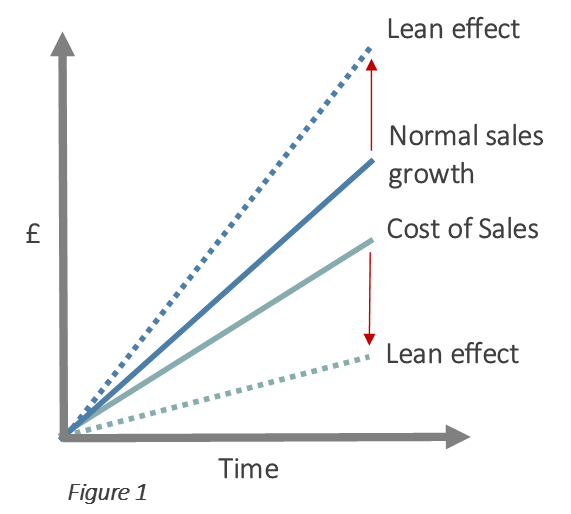

But why should S&M people embrace lean? Well, at a fundamental level, lean promises to not only lower the cost of sales, but also improve sales growth, as illustrated in Figure 1. Of course, this is not guaranteed and there are several other factors that will influence matters, such as general market conditions and competitor behaviour, but the opportunity for this win-win situation should been enough to persuade S&M sceptics to embrace lean ideas.

The key task is to engage with S&M managers in a way that will make them want to positively adopt lean, so that they think in terms of processes and value streams and start to examine how they approach their work and re-design it along lean lines. The behavioural change required may be challenging, though appealing to self-interest certainly has a place, especially since the culture of bonuses and incentives is all pervading in the S&M world and an improvement methodology that has the potential to make targets easier to achieve is bound to raise inquisitive eyebrows.

Finding the right way to communicate is also critical, since the language of lean is a long way off the language of S&M and so some translation is necessary to ensure that this does not become a barrier to acceptance.

Process Thinking in S&M

One of the great system thinkers and influencers of lean thinking, W. Edwards Deming, said “if you cannot define what you are doing as a process, you do not understand what you are doing”, so unsurprisingly process thinking is at the heart of lean. It is not possible to develop a truly lean organisation if you cannot define what you do, how you produce or deliver, what the organisation does and how it does it. All organisations are built on processes, whether purposefully defined or not, and processes support the value stream and business strategy.

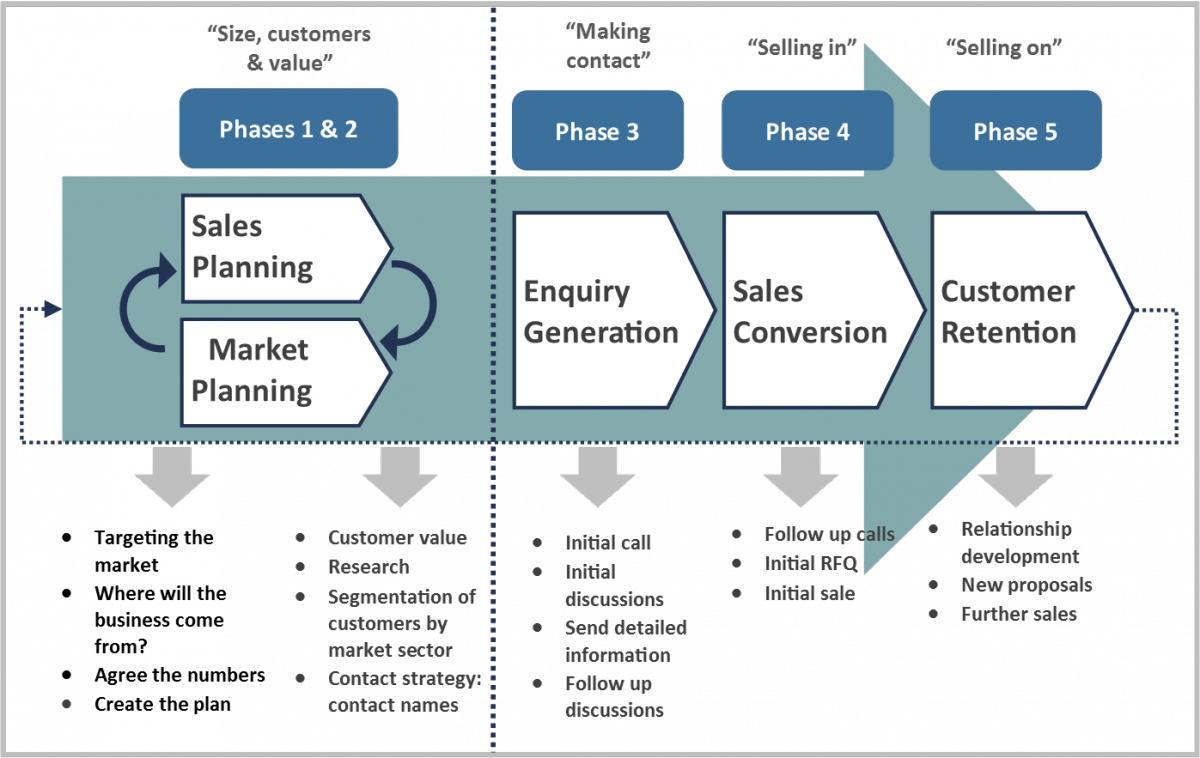

Anecdotal experience suggests processes are often not fully understood in S&M and particularly the case with senior S&M managers. It is therefore important to bring process thinking into the centre stage of S&M planning and the S&M Process Model is an example of a vehicle to achieve this, as shown in Figure 2.

The model emphasises the need to focus on four core S&M processes: sales/market planning, new enquiry generation, sales conversion, and customer retention (which includes added value services). S&M management must ask the following questions about their capability to deliver:

- How capable is the process to generate sufficient new enquiries of the right type (so you can actually produce and deliver the product/service offering profitably)?

- How capable is the process at converting new enquires from either new or existing accounts into actual sales (the conversion rate)?

- How capable is the process at maximising sales by offering additional product/service offerings to existing customers once a relationship is formed and trust established?

- How capable is the process at retaining customers of the right type?

These processes drive S&M performance and if one or more is not operating effectively, then the root causes need to be identified and addressed in order for it to improve.

Lean thinking principles and techniques can be used to develop a performance improvement plan and maintaining customer focus – which will include, for example, identifying the root cause of problems, removing waste and bottlenecks, improving process flow and gaining a better understanding customer needs.

Experience suggests that in SMEs the overall process is weak at the front end, with typical symptoms being an over reliance on one or more existing customers, a lack of selling skills and ability to develop relationships. In larger organisations, there are often issues towards the middle and end of the model, such as the inability to sell additional products to existing customers or issues with losing customers through poor relationship management.

Lean Thinking Principles

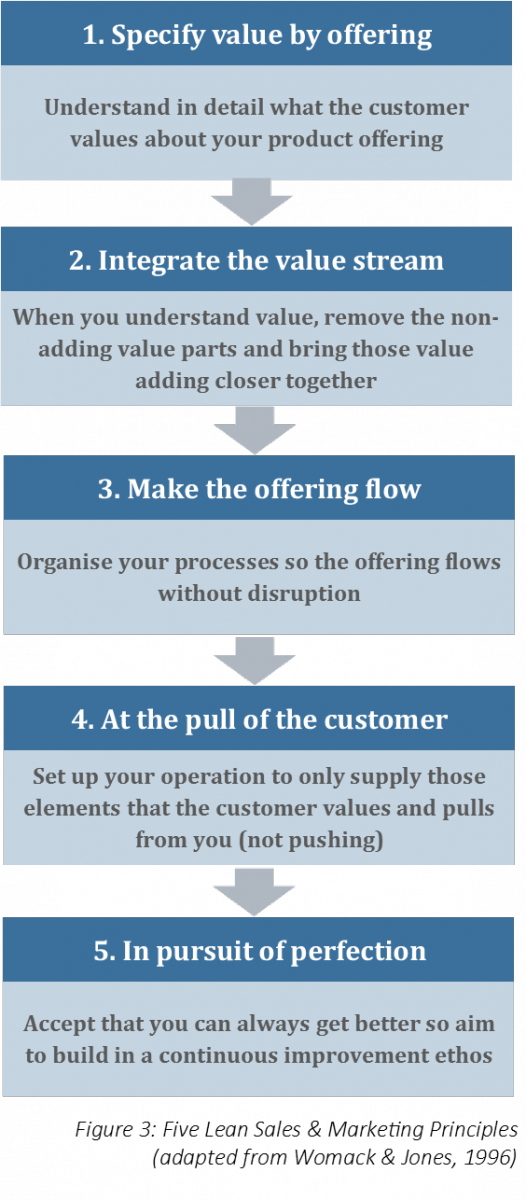

Womack & Jones in their seminal book Lean Thinking proposed five ‘lean principles’ that can be used as a framework to guide lean implementation. These principles can be readily adapted and used in an S&M context and provide an overarching framework for developing a lean S&M approach, as illustrated in Figure 3.

The first principle – understanding what the customer actually wants – (the voice of the customer – VoC) is central to lean thinking and, not surprisingly, equally fundamental to S&M. As those closest to customers, the S&M function, is usually tasked with understanding their needs and defining the detailed offering, though how much of the understanding is based on objectivity and how much on subjectivity is a moot point. A further complication is that in some sectors actually identifying the customer is problematic, as buyers are not always the final consumers of the product.

The first principle – understanding what the customer actually wants – (the voice of the customer – VoC) is central to lean thinking and, not surprisingly, equally fundamental to S&M. As those closest to customers, the S&M function, is usually tasked with understanding their needs and defining the detailed offering, though how much of the understanding is based on objectivity and how much on subjectivity is a moot point. A further complication is that in some sectors actually identifying the customer is problematic, as buyers are not always the final consumers of the product.

The second principle is about ensuring that all the elements of the S&M process are integrated and flow along the value stream. The four core processes of the value stream are the key drivers, each with specific phases of activity which should only comprise of value adding activities.

Typical non-value adding (wasteful) examples include:

- Using substantial resources to collect customer information, for example from surveys, and then not being able to interpret it or gleaning no insights from its analysis.

- Having a customer care programme which is misaligned to the specific needs of the market.

- Spending significant resources generating sales leads for the wrong type of customers.

- Giving too much attention to customers of the wrong type.

- Producing reports that are not read, do not lead to action or do not inform decision making.

- Multiple approval sign-off levels.

Waste removal can be achieved by undertaking a mapping exercise that enables non-adding value activities to be highlighted and considered for elimination. Value stream mapping is a valuable skill for individuals and teams. There are many types of mapping tools and having an appreciation of where and when to use the appropriate mapping tool can prove a real benefit to improving S&M performance. For example, the Big Picture Map might be used to scope out and gain a high level overview of a situation – it copes easily with the bigger issues and enables a wider perspective of an overall picture to be achieved. At a smaller scale, a four field map might be used to design or redesign a quotation process with the objective of reducing the time taken to process and enquiry.

The third principle is about flow and many lean thinkers contend that this is the essence of lean – ensuring that value adding activities flow quickly and smoothly through the value stream. From an S&M perspective, it is about making sure that all elements in each part of the four core processes exhibit continuous flow in order to make them efficient and effective.

Common symptoms of a lack of flow in S&M processes include:

- Overburdening of people through excessive work load backlogs in specific parts of the process.

- Excessive variation in process that are meant to be relatively standard.

- Unevenness of the workload demand.

- Too much non-value adding activity (waste) in processes

Principle four is only take action at the ‘pull’ of the customer. The opposite of pull is ‘push’ – that is, trying to give the customer something that may not be valued. Pull in classic lean manufacturing terms is about ensuring that a product is only made for known demand, avoiding a make to forecast mentality (some even contend that forecasts are either ‘lucky or lousy’!).

In the S&M world, the benefits of adopting this approach are specifically related to work patterns throughout the process, in that work is organised only in response to pull, or real demand, from the customer. Specific benefits include:

- Highlighting issues with workflow, including backlogs

- Enabling an alignment of skilled resources to demand

- Highlighting opportunities for continuous improvement

The fifth principle – in pursuit of excellence – is where every activity undertaken by every person in every part of the S&M process is focused on adding value aligned to the needs of the customer.

It is an ongoing mission, where those working on S&M processes are trained to recognise and then remove successive layers of non-value added activities as part of continuous improvement practice. This represents a cultural shift, require behaviour changes and takes time to embed.

Summary

S&M managers seeking to improve performance will find that adopting a lean approach offers them an effective and appropriate set of tools and techniques to help in realising their goals. When considered as part of a wider integrated lean transformation programme, the benefits will be felt across the business.

The benefits are primarily based on introducing process thinking and understanding to S&M staff. Process thinking has not generally been part of the vocabulary of S&M managers, who perhaps consider it as confining and restrictive, stifling the creativity required in their work. However, it can be argued that adopting lean ways and ‘managing by fact’ does assist in creative thinking and defining direction. For example, ‘visioning’, is a key part of effective direction setting and strategy formation and by gaining a much clearer picture of what customers’ value, S&M managers will be able to better align their offerings with the needs of their customers and more effectively than their competitors.

Understanding the concept of the value stream can offer real benefit to the S&M manager, as this clarifies what actually does and does not add value from their customers perspectives. Having the ability to visualise value streams and the processes within them, helps in root cause analysis and helps convert reactive behaviour, where processes are out of control, to highly focused and proactive behaviour where processes are in control. And of course, processes in control will flow more effectively.

Lean’s focus on customer value as a route to competitive advantage should sit very comfortably with the S&M community, since this should be their prime task in any business and getting a good understanding of the VoC has the potential to be a real differentiator and order winner. There are a range of VoC tools to help the S&M practitioner gain deep insights into customer value, as well as develop strategy, refine existing products and define new products.

Lean is applicable to S&M, since S&M is made up of processes, just like other parts of a business; and once activities are viewed and analysed as processes, then the opportunities for improvements are revealed. The particular advantage of this in S&M is that resultant productivity improvements can not only reduce the resources required to generate sales, but also increase sales through a better understand of customer needs.

Behavioural change will probably be necessary in most situations, which is invariably challenging and not without risks and the development of lean culture is a long term journey. However, important immediate gains can accrue as soon as there is a detailed understanding of S&M processes and clearer appreciation of customer value, paving the route for the development of a sustainable, continuous improvement S&M way.